- Harman

- ABOUT US

-

BROILER

-

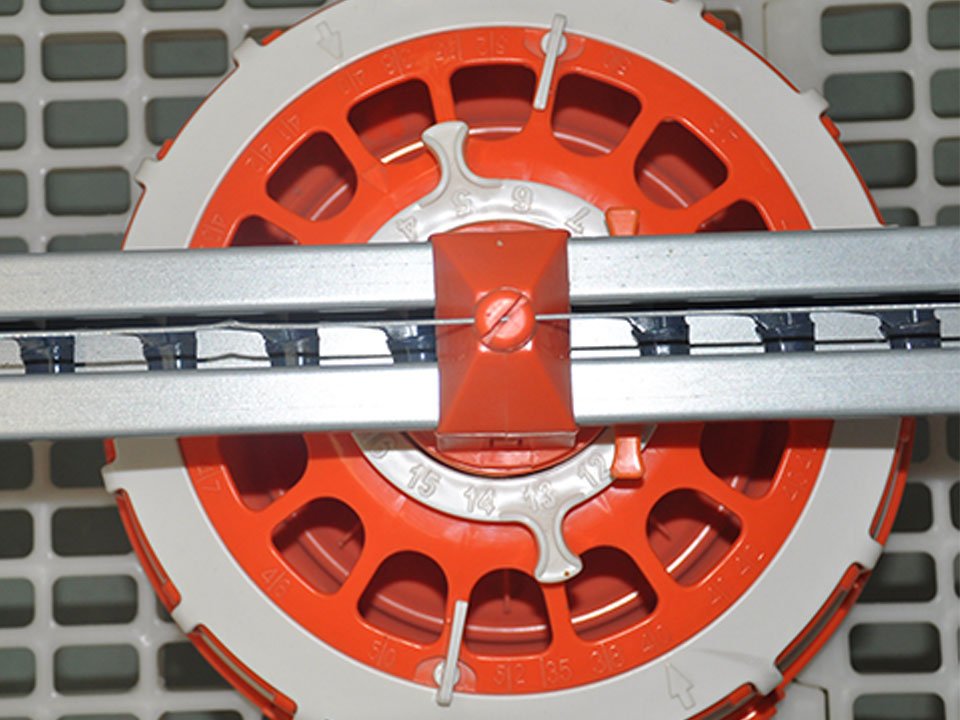

Feeding system

Feed silo conveying system Broiler pan feeding system 1 Hopper Feed pan Motor Poultry farm equipment broiler feeding system Broiler pan feeding system Automatic farm equipment Main feeding line silo and hopper -

Drinking system

Regulator Water Filter Nipple drinker Nipple drinking system Square water pipe with nipples Copy big hersdman -

Ventilation System

Air inlet 1 Ventilation fan Light trap Cooling pad system Tunnel door system Curtain sytem Air inlet Cooling pad -

Lighting system

Lighting system1 -

Plastic Slat

Poultry slat system 1 Poultry slat system Poultry Slat Slat -

Transfer Box

Birds transfer box -

Organic Fertilizer Machine

Organic Fertilizer Machine1 -

Environment Control System

Control System1

-

-

BREEDER

-

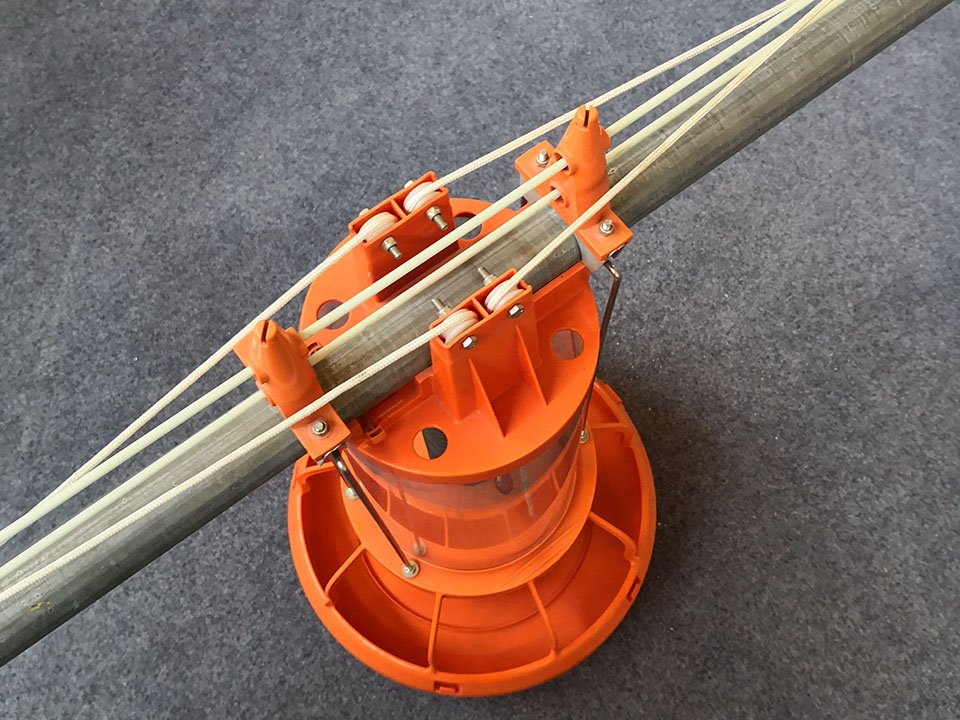

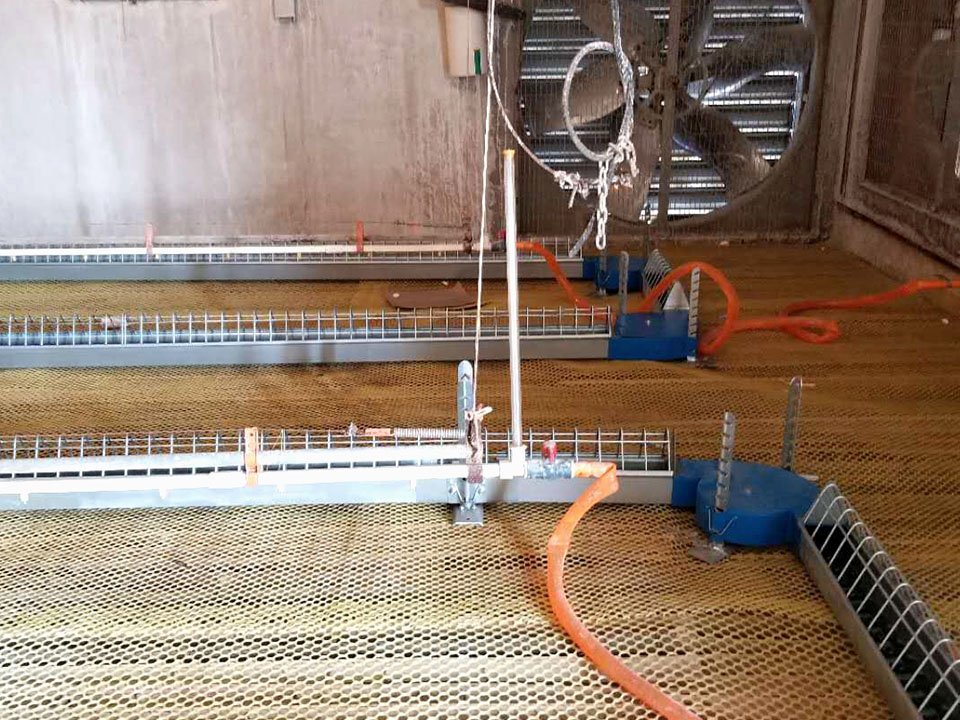

Feeding system

Breeder pan feeding system1 Breeder Metering barrel pan for male Chain Feeding System ( bracket support type ) Main feeding line silo and hopper1 Breeder pan feeding system Chain Feeding System Automatic breeder farm equipment -

Drinking system

Nipple drinking system1 Regulator 1 Nipple drinker1 Square water pipe with nipples1 Filter Copy big hersdman1 -

Ventilation System

Ventilation fan 1 Side wall air inlets are suitable Light trap with reasonable Cooling pad system this Tunnel door system 1 Air inlet 2 Cooling pad 1 Curtain sytem1 -

Poultry Nest

Auto communal nest (galvanized type) Auto egg nest 1 Manual Egg nest Auto Communal Nest Auto egg nest individual holes Auto Communal Nest Chicken egg nest system,Automatic Manual egg nest 24 Holes Chicken egg nest system -

Plastic Slat System

Breeder Plastic Slat Poultry slat -

Lighting system

Lighting system -

Heating system

Heater system -

Generator

Generator -

Organic Fertilizer Machine

Organic Fertilizer Machine -

Environment control system

Control System -

Other plastic accessories

Sheep slat floor Duck laying nest Baby chicken transfer box Egg nest mat -

LAYER

A frame cage Battery cage -

EGG CONVEYOR

Egg conveyor -

CATTLE FARM

Cattle farm

-

- PIG

- STEEL PREFAB HOUSE

- TURN-KEY SOLUTION

- INFO

- CONTACT

苏公网安备32090202001391号

苏公网安备32090202001391号