1. High feed conveying ability , 36m/minute, 2.0 ton per hour ;Even and quick feed delivery .

2. Stable working , low fault rate , low maintenance cost , long service life .

3. Different motor capacity due to different house length.

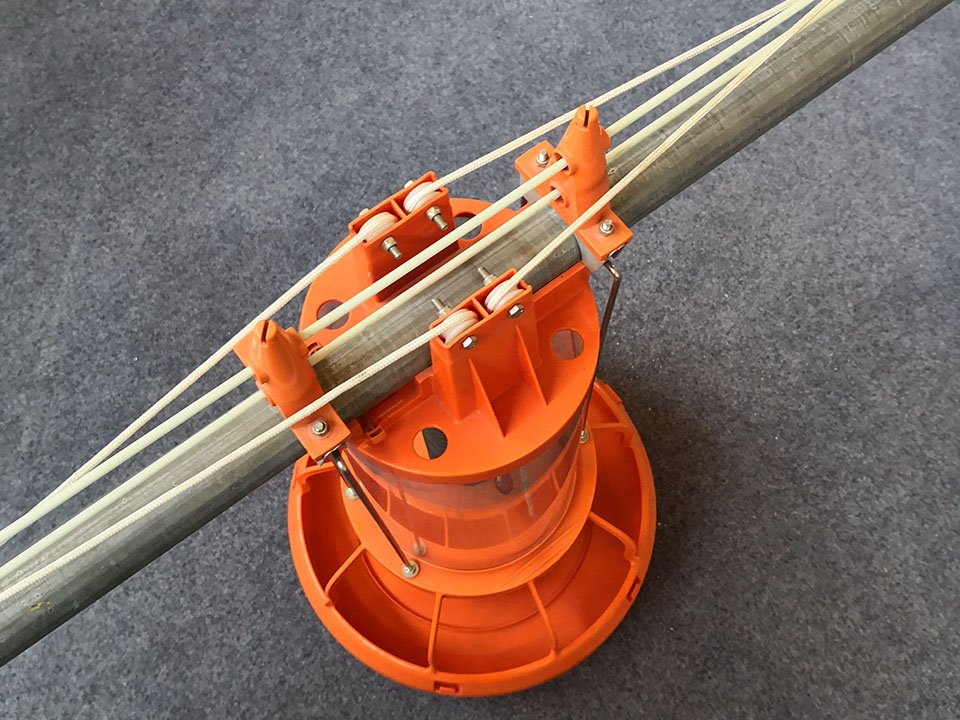

4. High rigid 90° cast- iron corner , good corrosion and wearing resistance .

5. 275g/m2 hot galvanized steel hopper with feed return wheel ,preventing feed overflowing ; Hopper size can be customized .

6. South Africa chain , quality reliable , lifetime warranty .

7.Feed line height is easy to be adjusted according to birds age .

Stocking density (birds/m2) | 4.5 -5.0birds |

No. of birds/m of feed trough | 10-13 birds/m |

Feeding type | Controlled |

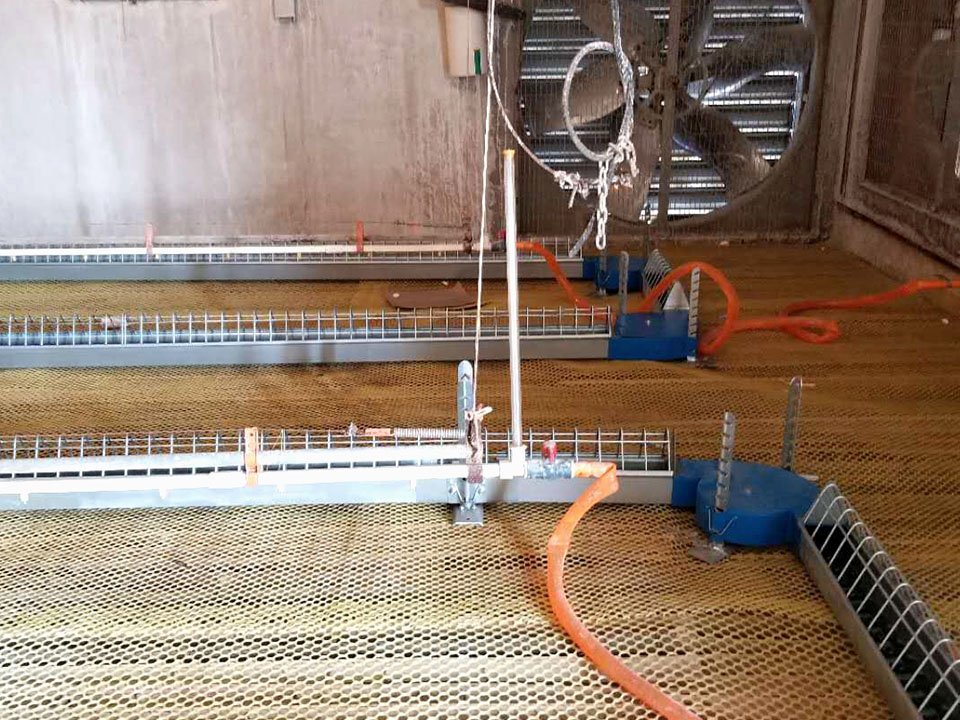

1.Automatic Main Feeding System

Main feeding system delivery feed from silo to each vice hopper in the poultry house. There is one feed level sensor at the end of main feed line which control the motor on or off automatically .

Item | Consists goods | Specifications |

1 | feed silo | 2.8t/4.4t/14t/16t/22t/28t or customized, hot galvanized steel or fiber reinforced plastic |

2 | big feed hopper | 600kg/800kg/1200kg or customized,hot galvanized or paiting material |

3 | drive system | Italy Transtecno brand,split motor with gear box,1.1kW/1.5kw,220/380v,50hz,IP55,insulation level:F |

4 | sensor | world top class products |

5 | delivery pipe | world top class,diameter 75mm or 90mm |

6 | auger | South Africa,model 20/060,20/071,lifetime warranty |

Remarks | Silo foundation and the embedded parts should be borne by the buyer |

| | | |

2.Automatic Breeder Chain Feeding System

Chain feeding system has high feed conveying ability,36m/minute, 2.0 ton per hour ;Evenly and quickly feed delivery ; Stable working , low fault rate , low maintenance cost , long service life .

苏公网安备32090202001391号

苏公网安备32090202001391号